Selection and use of control cables

With the continuous development of the industrial field, the current demand for industrial control cables is also increasing, but some people do not consider the interests of consumers, make huge profits, mass-produce counterfeit products, and disrupt the market. A cable is small, but it has a lot of responsibility. Most fires are caused by aging or poor quality cables, resulting in numerous personal and property losses. Therefore, you need to carefully purchase industrial control cables that are produced in strict accordance with national standards.

The rated voltage of the control cable cannot be lower than the working voltage of the circuit, and must meet the requirements of temporary and power frequency overvoltage that can be tolerated. Long high-voltage cables are usually protected by vertical differential protection, so control cables such as protection and monitoring signals are usually routed parallel to high-voltage cables (often called pilot cables). When a single-phase ground fault occurs in the primary system, the electromagnetic detection may exceed the insulation level of the common control cable due to the power frequency overvoltage value on the control cable.

Here, the editor discusses some new problems in the selection and use of control cables in recent years for reference.

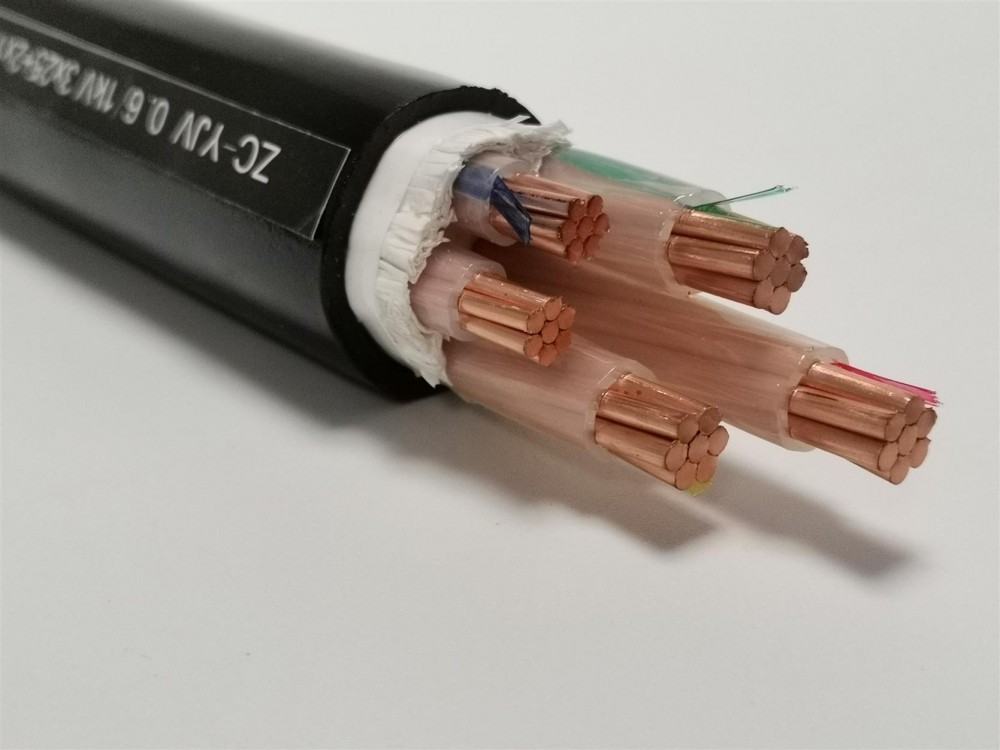

1. Main series of control cables:

At present, the main products of control cables are PVC insulation, natural styrene-butadiene rubber insulation and polyethylene insulation. In addition, there are cross-linked polyethylene insulation and ethylene propylene rubber insulation products, and the oil-impregnated paper insulated lead-packed control cables produced in the early years have been eliminated.

2. Measures to ensure the normal operation of the control cable and prevent interference:

In order to reduce insulation damage, mechanical damage or the spread of control cables in the event of fire, the relevant national standards stipulate that dual protection systems such as current, voltage, DC power supply, and trip control circuits that need to improve reliability use independent control cables.

3. After the control cable is put into operation, there is electrical interference between different core wires of the same cable and between adjacent parallel cables. The main causes of electrical interference are:

(1) Electrostatic interference caused by capacitive coupling between iron cores caused by external voltage;

(2) Electromagnetic induction interference caused by current. Generally speaking, when there is a high-voltage and high-current noise source nearby, the electrical interference is more serious. Since the distance between the core wires of the same cable is very small, the degree of interference is much greater than that of adjacent parallel cables.

4. Measures to prevent or reduce electrical interference mainly include the following three aspects:

1. When electrical interference occurs, the control cable shall not be used in circuits that will have serious consequences.

2. The inner shielding layer of double shielding or composite overall shielding should use some grounding, and the outer shielding layer can be grounded at 2 points.

3. When choosing two-point grounding, it should be considered that the shielding layer should not be burned under the action of temporary current.

Last:What is the cause of the problem with the high voltage cable?

Next:没有了